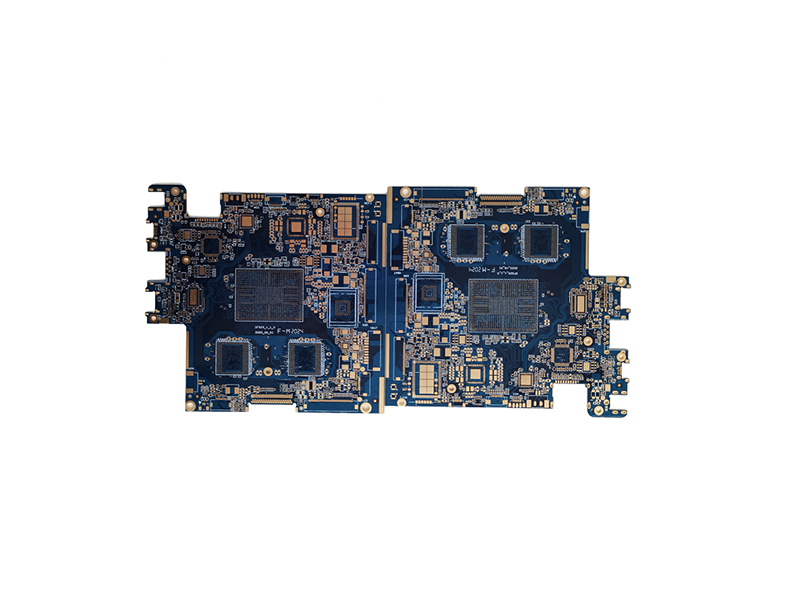

10 layers Any layer HDI PCB

10 layers Any layer HDI PCB

2023-04-25

Board Material: FR4 IT180A

Number of layers: 10 layers

Boardthickness: 0.8mm

SurfaceFinish: immersion gold + OSP

Inner layer Copper thickness: 0.5OZ

Outer layer Copper thickness: 1OZ

Line width/spacing: 2.5mil/2.5mil

Special process: anylayer1-2,1-3,1-4,1-5,1-6,1-7,1-8,1-9,1-10

Send Email: fiona@beton-tech.com to UsCustomer Background

Company Location:Mexico

Application:GPS system, Car video system, Car communication system, Driver assistance system

Field:Automobile

Service:PCB Prototype, PCB Manufacturing, Mass production

Project Background

This is a Mexico automobile manufacturing company.He knew our company through his friend’s introduction.His friend manufacture HDI flex pcb in our factory. So he recommend our factory to him. As we all known, the Automobile products is very strict. The Mexico customers needIPC6012 CLASS 3 standard with ISO9001 and ISO/TS16949 certification.

Project Challenge

Ÿ Customers demand fast delivery and high-quality prototypes, as well as large-scale production so that they can accelerate time from research and development to market and expand more potential markets.

Ÿ HDI Anylayer interconnection is a high-density connection technology with high technical threshold. The main processing difficulties are: interlayer alignment, laser drilling, hole filling electroplating, fine line processing.

Ÿ The core board of any HDI layer and the pp (adhesive sheet) between layers are extremely thin, and the use of ultra-thin core board and pp will bring great challenges to PCB production.

How to serve

(1) Provide fast delivery and high-quality any layer HDI prototype service.

(2) The core board of any layer of HDI board is ultra-thin. After the core board is copper-reduced and browned, it is directly drilled with a CO2 laser.

(3) 24-hour engineers provide technical support online.

(4) Reliability assurance after multiple reflows and expansion and contraction control after multiple pressings.

(5) Because the customer was eager to test the original board for mass production, we applied for an urgent order for him, successfully produced any layer HDI prototype within 1 week, and arranged the delivery as quickly as possible.

Results andBenefits

Ø After receiving the prototype drawing from the customer, we completed the prototype order within 1 week.

Ø AOI, X-ray, functional testing, and manual visual inspection are carried out before shipment to ensure the high quality of Any layer HDI products. No feedback on poor quality issues.

Ø For mass production, we have sufficient materials in stock, arrange production in the fastest time, and provide more time for customer's later assembly.

HDI PCBs are useful in the automotive industry because reducing weight improves performance. As modern vehicles become increasingly connected and computerized, HDI PCBs are critical to operation. Today's cars have around 50 microprocessors for engine control, safety features and diagnostics. HDI PCBs are integrated into advanced features such as rear view cameras, in-vehicle WiFi and GPS, and backup sensors. Each layer in the Any layer HDI PCB stackup consists of HDI layers. Additionally, any layer HDI design allows the use of copper-filled microvias to connect conductors on the HDI layer.

If you have any layer HDI PCB demands, please contact me at cathy@beton-tech.com. Our engineer will provide professional advice and manufacture good quality any layer HDI PCB.